Introduction

![]() Thanks to a constant collaboration with its clients, most of them famous shipyards such as NAVAL GROUP, NAVANTIA, KOCKUMS AB, BAE SYSTEMS, DSME, HII, or Energy clients such as AREVA, EDF, ALFA LAVAL, OVIVO or others markets with clients such as CRISTAL UNION, ARCELOR MITTAL, IHC, Fapmo has developped experience and technologies unmatched in the world for centrifugal pumps.

Thanks to a constant collaboration with its clients, most of them famous shipyards such as NAVAL GROUP, NAVANTIA, KOCKUMS AB, BAE SYSTEMS, DSME, HII, or Energy clients such as AREVA, EDF, ALFA LAVAL, OVIVO or others markets with clients such as CRISTAL UNION, ARCELOR MITTAL, IHC, Fapmo has developped experience and technologies unmatched in the world for centrifugal pumps.

Based on its great experience and technologies, Fapmo design department is able to work on all the requirements under any specific standards in order to meet Customers needs.

Furthermore, Fapmo has the rare ability to perform all the tests needed in order to prove Customers criterias are met.

Examples of Pumps and characteristics

Submarine and surface ship pumps

Depending on the requirements and pumps, Fapmo can commit (and prove) on some of the following characteristics :

- Ability to withstand shock > 120g

- Low pressure fluctuation level on the whole range of the pump operation

- Very low vibration and noise (<< 55dB)

- MTBF > 10 years

- Self priming bilge and ballast pumps working in any position of the boat

- 100% compliant under any standards

- Compacity : approx 30% less with canned motor

- High efficiency pumps with low electrical consumption

- Non magnetic pumps

Fapmo is also able to create a co-conception program with Customers in order to improve or develop a specific technology.

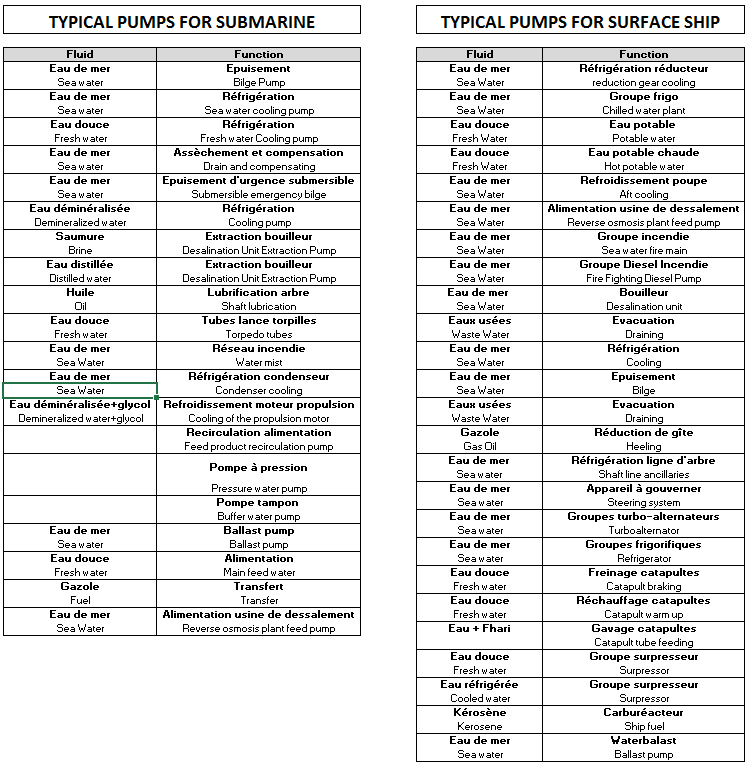

Example of centrifugal pumps we provide for submarines and surface ships :

Civil pumps

Based on its experience and products, Fapmo provides :

- High efficiency pumps

- Ability to withstand high temperature (>>270°C)

- Capability to work with slurry liquids, ashes, brine, abrasive, acide, phosphate etc…

- 100% compliant under any standards (ASME, RCC-M….)

- High pressure “back to back”

- High flow and large diameter

- Very low NPSH

Materials

Typical materials handled for all Fapmo pumps are the following :

- Titanium

- Composite

- Cast iron

- Nickel alloy

- Hastelloy

- Duplex/Superduplen

- Aluminium bronze

- Ni resist cast iron

- Uranus

- Special steel if required

Technologies

Fapmo masters all type of technologies for our pumps :

- Magnetic driven pumps

- Wet rotor pumps (canned)

- Multistage pumps

- Self priming pumps

- Submerged pumps

- Close coupled pumps

- …

Fluids

Below example of fluids Fapmo used to deal with :

- Fresh water

- Sea water

- Demineralizer water

- Water with ashes

- Phosphate

- Acide

- Brine

- Grey water

- Abrasive slurries

- Ammonia

- Hot water (>270°C)

- Muddy water

- Water +sand/silica/chalk

- Cement

- Potash

- Magnétite pulp

- Phosphogypsum

- Coal pulp

- 1rst carbonization juice

- Vacuum